Pressatura

Il processo di pressatura viene effettuato esclusivamente con paraffina in polvere o trucioli di paraffina molto fini.

Durante la produzione, la paraffina liquida viene spruzzata su un tamburo in acciaio inossidabile che la raffredda e la solidifica immediatamente. Questi granuli fini vengono convogliati alla pressa per candele tramite un sistema di tubi.

Nella pressa, la paraffina viene compressa in diverse forme, ad esempio cilindri o sfere. Contemporaneamente, lo stoppino viene inserito con un ago tubolare. L'intero processo dura solo pochi secondi. Subito dopo la produzione, i grezzi delle candele stampate vengono immersi nel colore o verniciati.

Colata

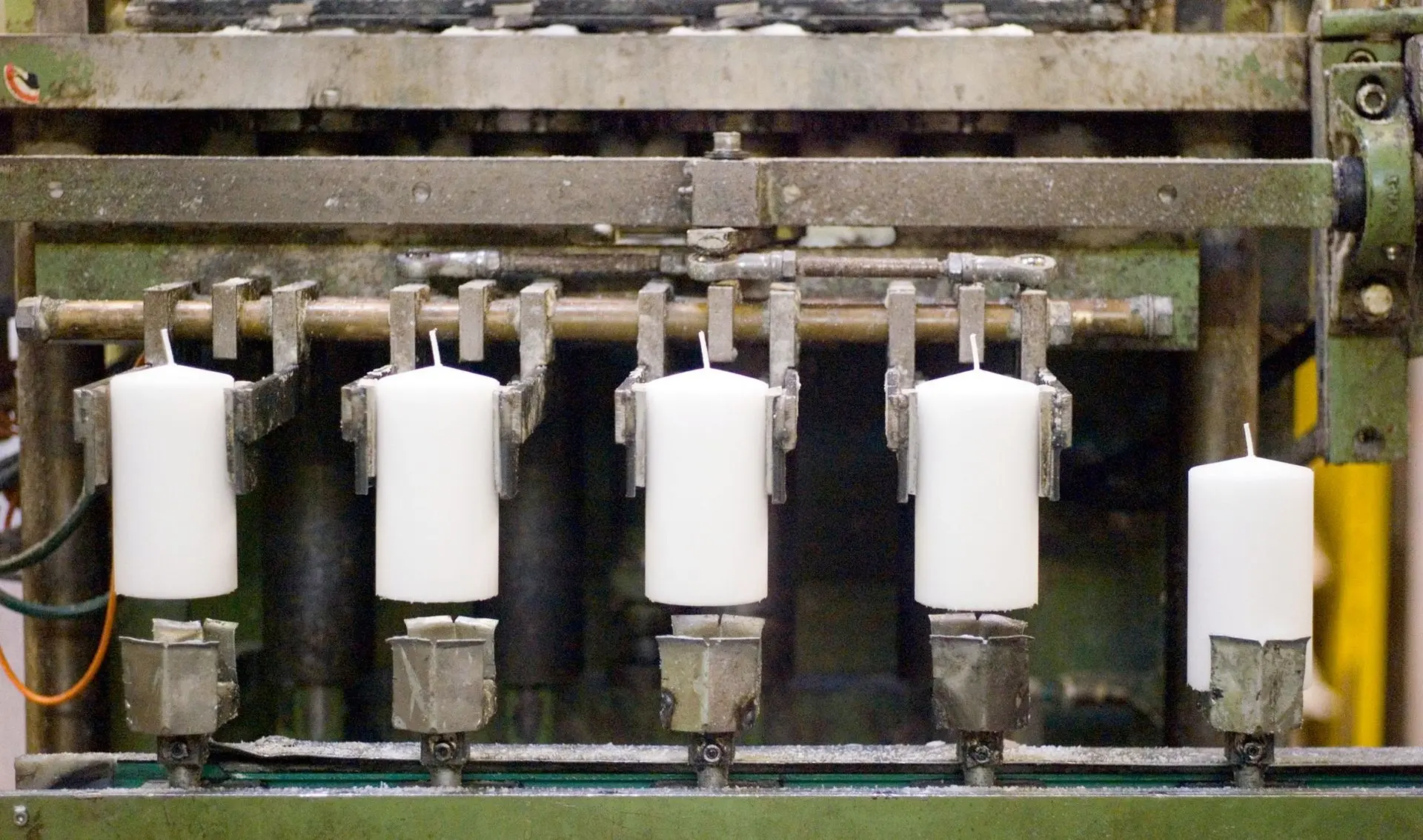

La tecnica della colata è il procedimento più antico per la fabbricazione delle candele. Il principio di base non è mai cambiato. Uno stoppino viene posto al centro di uno stampo qualsiasi e ricoperto di cera liquida. Una volta solidificata, la candela finita può essere rimossa dallo stampo.

Per produrre molte candele, venivano allineati diversi stampi uno accanto all'altro. È su questo principio che sono state poi progettate le macchine per la colata delle candele.

Il processo di colata è particolarmente apprezzato perché consente di utilizzare stampi e miscele di cera molto vari. Forme di candele originali, come candele a forma di stella o di figurine, nonché candele colorate nella massa. Le candele in stearina pura possono essere prodotte solo mediante colata.

Tiraggio

Originariamente artigianale, questo metodo di produzione è stato modernizzato e automatizzato negli ultimi decenni, tanto che ancora oggi molte fabbriche di candele continuano a produrre le loro candele in questo modo.

Diverse centinaia di metri di stoppino possono essere avvolti sui tamburi e messi in rotazione. La parte inferiore dello stoppino passa in un bagno di cera, dove viene ricoperta da uno strato di cera. Questo si raffredda mentre lo stoppino continua a girare, fino a quando non ritorna nel bagno di cera.

In questo modo lo stoppino della candela raggiunge il diametro desiderato. Una volta raggiunto il diametro richiesto, il cordone finito viene rimosso dalla macchina di trafilatura. Una macchina di taglio e fresatura sviluppata per questi impianti taglia il cordone di candele che arriva in continuo alla lunghezza desiderata e trasporta le candele tagliate verso un'unità di fresatura. Qui vengono fresati contemporaneamente la testa e il piede delle candele.

La macchina di produzione consente di produrre oltre 10.000 candele all'ora. Questo processo di produzione è utilizzato principalmente per candele domestiche e candele da altare di alta qualità.